RTG3800

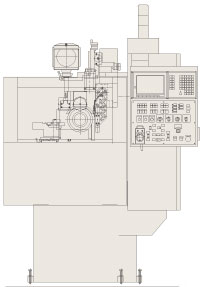

CNC Tool Grinding Machine

The RTG-series is the world’s highest-level grinding machine in the 21st century. It was developed from our long years of expertise and technological know-how from dealing in PCD grinding machines by KANEHIRA. They are a leading grinding machine manufacturer with over 30 years experience in the manufacture of PCD tool grinding machines.

デジタルだから出来ること

By using digital camera, a initial preparatory work performs smoothly, and various measurement and saving measurement image in real time.

Saving a work before and after the processing, so that it contributes quarity assurance.

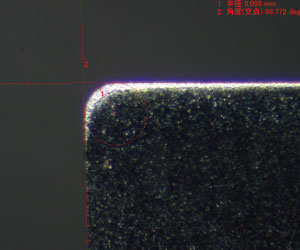

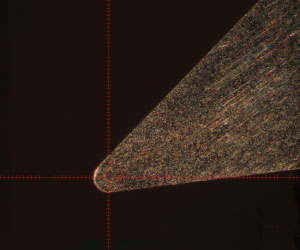

Observing from low to high magnification by a zoom lens. Especially small diameter nose R set smoothly in high magnification.

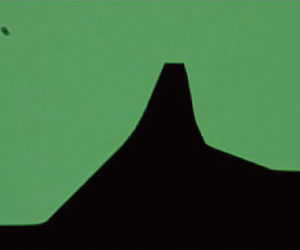

Crack or separation of work can be observed by epi-illumination. Especially it demonstrates on regrinding process.

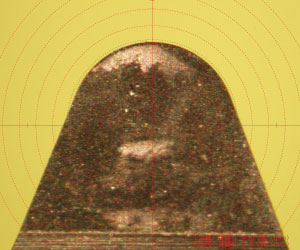

Concentric circle, semicircle, viewing cross line

Epi-illumination+Transmitted illumination

Concentric circle, semicircle, viewing cross line

Epi-illumination

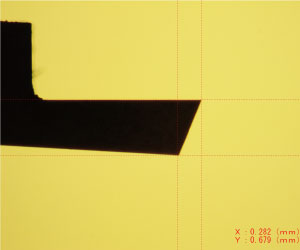

XY distance measurement

Transmitted illumination

Camera image 200X

Semicircle,Angle measurement

Epi-illumination

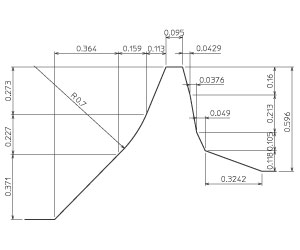

Drawing of workpiece

Axis composition

Processing example

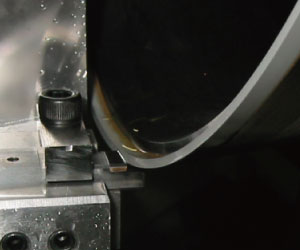

Cylindical mini work piece grinding attachment

NC cylindrical grinding: Machining a small-diameter grinding wheel using an index device

PCD cutter grinding

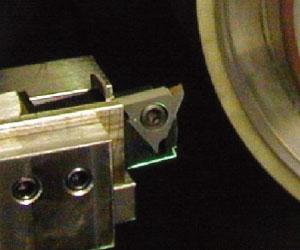

Machining a disposable tip (The tip breaker is machined at the same time)

PCD cutter

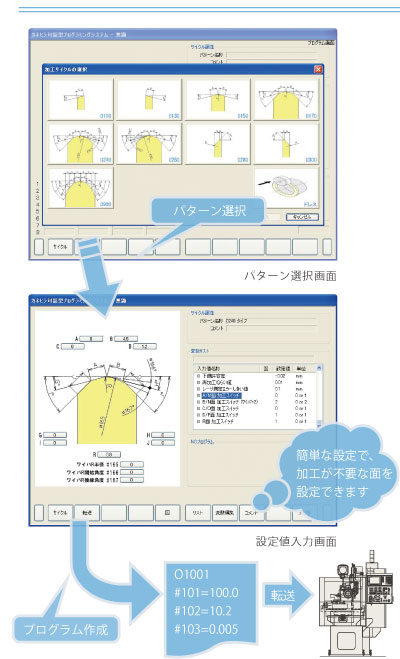

Interactive program

Features

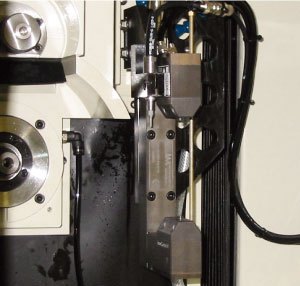

Machine mounted laser measurement (optional)

The Blum laser system measures the configuration of the workpiece on the machine,completely automatically. The results of the measurements are used to prepare for the next machining session,to reduce the time needed for highly accurate machining. Setup time is also substantially reduced.

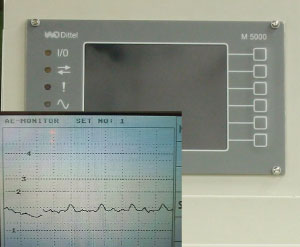

AE sensor system (option)

The AE ultrasonic sensor incorporated in the main spindle alerts the operator to any micro-vibration which might occur in the main spindle during operation. The alert is shown in real time on the monitor. It can also be used for checking the resistance while grinding,for sensing contact,and other purposes.

Machine mounted dresser

The high-performance dresser mounted on the machine continuously keeps the diamond wheel aligned and flat,for the best accuracy. This provides high accuracy,great uniformity ,and high efficiency to your machining operations. Programming for constant compensation will get the most out of the NC.

High-rigidity bed

A number of thick ribs are used for the machine,after careful consideraton of the distribution of mass on the superstructure. This provides the rigidity required of a PCD tool grinding machine,as well as the ability to absorb vibration.

Space saving

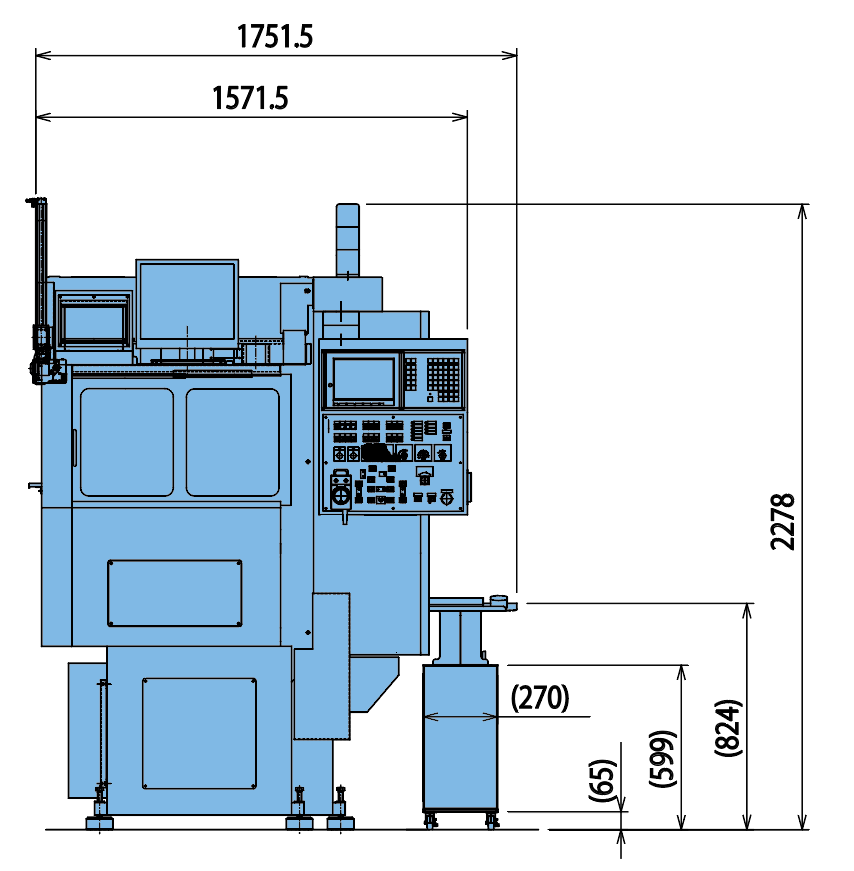

The entire machine is enclosed snuggly in a housing that uses only a very small floor space for installation (1550mm x 1742mm).There are no unnecessary projections of doors or servomotors. The operation panel is carefully designed and organized for easy operation.

User macro

A great many user macro programs(some macros are optional) are possible, for easy and efficient operation. The machine comes with some macros already installed. Even operators who are not familiar with NC machines can easili progam a macro. We also stand ready to make customized macros, according to a costomer’s machining needs.

The futures of RTG3800

- 8 axes NC control

- Lazer measuring

- AE sensor system

- NC on-board dressing

- Digital zoom camera device

- With automatic loader

- A workpiece is set on exclusive holder

- Exclusive holder with ID chip

- Micron folder with tempreture adjustment

新しく追加されたオプションによるメリット

Digital camera

Demonstrating power to smoothly start new item.

ID

Mixture flow production is possible by ID.

ID aquires the variations of workpieces and corrects them.

ID+Digital camera

Utlizing quality control and quality assurance by using and saving ID data of workpiece images.

Interactive program

You can create programs easy by PCD tool grinding interactive programming system that combines KANEHIRA’s know-how of PCDgrinding over many years. It can response to change shape of item promptly.

ハードディスクレス・オープンCNCの採用

Reliability of open CNC in PC is improved greatly. There is no risk of data loss by crush.

Automatic loader

A nighttime unmanned operation is possible.

Standard specifications

-

Dressing axis

On machine dresser

Dressing wheel 100D

Control

Manual on control panel

-

Wheel spindle

Motor type

AC spindle motor

Motor power

1.5kW

Rotation speed

1,000~4,000min-1

Angular angle control

NC control (B axis)

Angular angle

0°-30°

-

Spindle head

Spindle head drive control

NC control (X axis)

Stroke

260mm

-

Work table

Cross table Left-Right drive control

Manual 40mm

Cross table Forward-Back drive control

Manual 40mm

Cross table Up-Down control

NC control 70mm(Y axis)

Table swivel

NC control ±95°(C axis)

Infeed table Forward-back move

NC control 115mm(Z axis)

-

In machine light

LED light

140LX

-

Grinding wheel

Wheel size (not attached with machine)

Taper cup type 200D x 65T x 60H

-

Control unit

FANUC

32iMB

Load-Unload interface

USB, Flash memory (without RS-232C connect)

Program memory

512KB

Program memory quantity

1000

Machining time, quantity display

No

Door interlock key

No

-

Illumination

Transmitted lighting

-

Cover of machine

Full closed cover

-

Lubrication

Automatic lubrication

-

Standard accessories

Tools

1 set

FANUC instruction book

1 set

Machine instruction book

inc. Electric circuit and Air circuit diagram

-

Language

Japanese

Instruction book, Name plate, PC

-

Color

KANEHIRA standard

7.5Y8/1

-

Machine weight

2,800kg

Option

- 【CCD camera unit】

CCD camera | 6 magapixel color CMOS

High precision zoom microscope | 1~5x

PC | Windows 7,HDD250G,DVD drive,Keyboard,Mouse,USB3.0,LAN

Monitor | 17 inch color LCD

Monitor magnification | 40-200x (zoom lens)

Measurement function | Scale,between two points,radius angle,calibration

Display soft | Cross scale,concentric circle,semicircle

Transmitted light | LED 6W

Camera | Reinforced-camera mount system

- 【Coolant unit】

A

Tank capacity / Pump | 60L / 60W

B

Tank capacity / Pump | 60L / 60W

Filter | Simple paper filter

C

Tank capacity | 120L

Filter | Micron filter temperature adjustment - Work table(X-table) digital display

- Signal tower

- Custom macro soft

- Auto measuring unit for wheel position

- Auto measuring unit for work form |

Used laser point gage - Auto measuring software for work

- Wheel axis acoustic unit | To know touching with a wheel

- Work loading unit

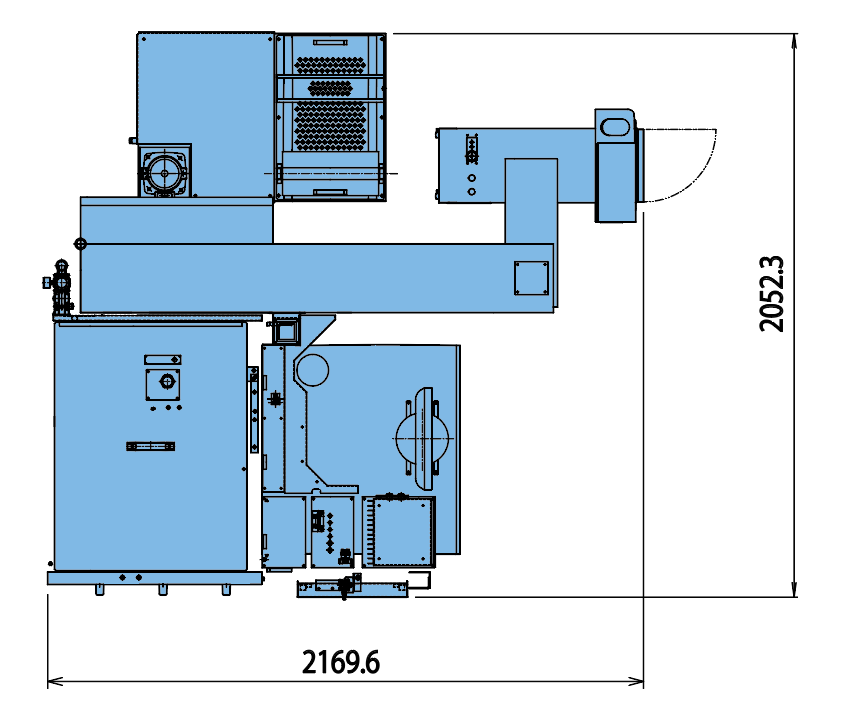

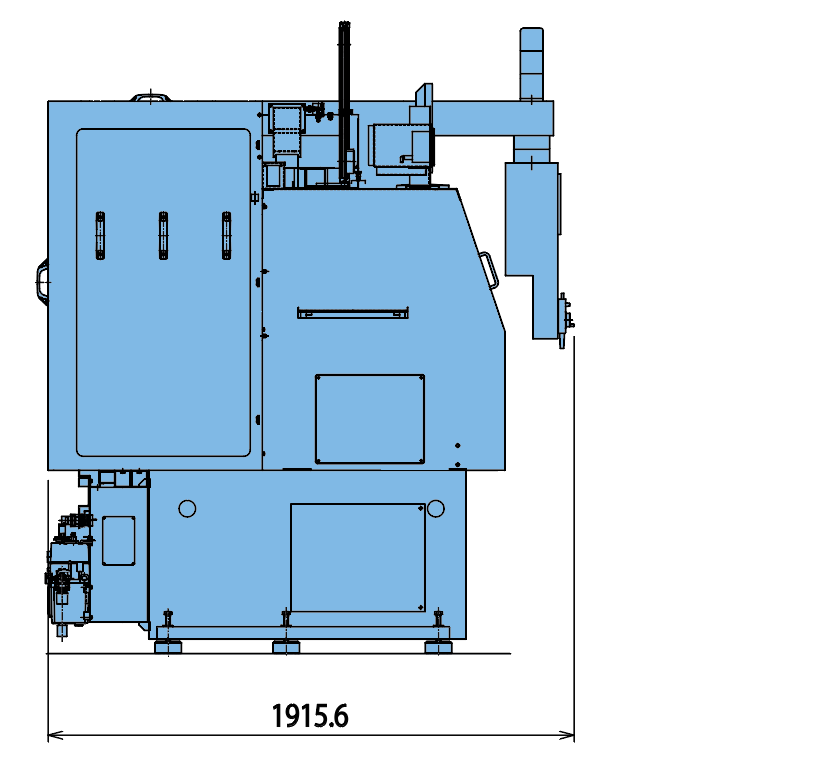

Machine dimension

CASES

OTHER PRODUCTS

Tool Grinding Machine

RTG1000

Tool Grinding Machine

RTG2000M

PAGE TOP