DFM210

Diamond Wheel Dressing Machine /CBN/Grinding Wheel(manual type)

Diamond wheel from dressing and truing machines are full-dressforming machines that perform high-accuracy from dressing and truing of diamond wheels as well as CBN wheels with outstanding efficiency.

More accurate wheel shape requires toprecisely process a workpiece.

Even if you have a high precision CNC grinding machine, an precise shape is not formed by a wheel that is distorted and wore the tip R.

DFM series can possible to adjust a tip R shape of wheel by easy action, and perform high accuracy processing.

Processing a work with precise can not by such a distorted wheel.

To achieve a high precision shape by correcting a shape of tip with high accuracy.

(The image of work piece by digital camera.)

Features of DFM-series

- The each parts of the machine posses high stiffness. Accordingly,diamond or CBN grinding wheels are formed at high accuracy.

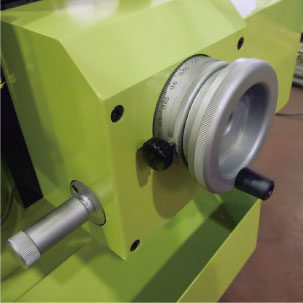

- The top of the work is an exchangeble type and is provided with a centering mechanism. For that reason, it is easy to mach the work with the flanges of every company.

- Oscillation of the grinding wheel spindle with a crank mechanism has a silent motion.

- This machine is combined by a compact design. For that,it is easy to work and not necessary for it to get a big space.

- It can combine many options economically suiting for various uses.(Auto in-feed, Swiveling)

A motion of machine in correcting a wheel

Formed work samples

Auto in-feed, Swiveling

This ratchet feed mechanism allows intermittent automatic infeed within the range from 0.0025mm (minimum) to 0.03mm (maximum), with the maximum auto-infeed amount being 50mm. The performance of this device is significant when machining requires fine infeed or takes long time.(optionally for DFM210)

Automatic swiveling is possible. Swiveling angle is set by the stoppers which allow precise setting while eliminating errors due to repetition of swiveling return motions. It is possible to process such as grinding tools exactly an arc(corner radii).(DFM410R)

The swivel drive adopts am airhydro-mechanism to secure smooth rotation of the wheelhead and to minimize the thermal deformation at the same times.

Increase of durability

It is true that the most cumbersome enemy against maintenance of accuracy and performance of a wheel forming machine are abrasive grains produced through forming operation.

Once abrasive grains that contain diamond or CBN particles enter the machine parts, they will invade and erode the movable parts andoptical system soon like a virus. We have given the utmost care to dustproof measures and coolant penetration for the DFM-series, and still continue to provide further improvements.

For the most important wheelhead swivel mechanism, a combined system of labyrinth and air purge is adopted for dustproof and waterproof measures. The swivel base is internally pressurized with 99.99% or more moistureless air to provide an air curtain to prevent external coolant splash and abrasive grains from entering the inside.

The effectivity of this system greatly contributes for improvement of the machine durability.

Options

Simple CCD camera (included monitor)

Allows precise monitoring of the work forming condition.

Wheel spindle angular offset device

Allows forming of both sides of as small diameter work by one chucking without turning it over.

Work spindle arbors

By making use of high-prection replacable arbors that fit various wheel flanges of different manufactures’grinders, the work spindle nose can be adapted to many types of wheel flanges at low cost.

Standard specifications

-

Grinding capacity

Max.dia. of work

D210mm

Min.dia. of work

D1mm

Max.width of work

25mm

Forming angle

±95°

-

Work Axis

Shank type

HSK50

Quill Type

D80mm

Motor power

(DC servo motor)120W

Rotation speed

100-400min-1

-

Work head

Back/Forth stroke

(Z axis)100mm

Left-Right stroke

(X axis)115mm

-

Dressing wheel

Max. wheel size

(Mad O.D.x

widthxI.D)D180x13xD31.75

Rotation speed

1,690min-1

Motor power

200W 4P

-

Dressing wheel

headManual feed

(U axis)Dial scale 0.005mm Handle 1 rotation 1mm

Oscillation stroke

(V1axis)0-25mm

Oscillation stroke

(V2axis)20mm

Oscillation speed

10-30rec/min

Oscillation motor

15W

Swivel angle

(B axis)±100°

Swing angle

Min. scale amount30sec.

-

Illumination

Transmitted lighting

-

Standard

accessoriesTools

1set

Machine

instruction bookinc. Electric circuit and Air circuit diagram

-

Language

Japanese

Instruction book, Name plate, PC

-

Color

KANEHIRA standard

5GY7/4(Green)

-

Machine weight

500kg

Option

- Coolant unit|60L tank, 60W pump

- Auto.infeed unit of grinding wheel spindle (standard spec. for DFM410/510)

(Intermittent infeed by rachet & interval timer)

|Feedrate0.0025mm-0.02mm - In-feed of oscillate synchronization

- Swivel base auto-swivel device (standard spec. for DFM410/510)

|Swiveling speed 6 degree/sec - 12 degree/sec - Wheel spindle stepless speed change (by inverter)(standard spec. for DFM410/510)

- Wheel spindle motor (DFM210)|0.4kW strengthen spindle

- Wheel spindle angular offset device(A axis) (standard spec. for DFM410/510)

|0-20° - Digital angle meter of wheel slide swiveling (standard spec. for DFM410/510)

|Min.display5′ - Digital angle meter ofwheel slide swiveling

|Min.display1′ - In-feed amount digital display

|Min.display0.001mm - Digital display of position of work slide (X,Z axis)

|Min.display0.001mm - Dummy piece test grinding attachment

- Splash guard

- Adjustable splash guard (Magnet type)

- Simple CCD camera (included monitor)(standard spec. for DFM410/510)

|17 /21.3 inch LCD - Digital CCD camera (included monitor) 40-200x zoom

|17 /21.3 inch LCD - Wheel flange

- Spring collet holder(φ1-16mm)

- Taper sleeve holder

- Special-purpose holder

- Special-purpose work spindle

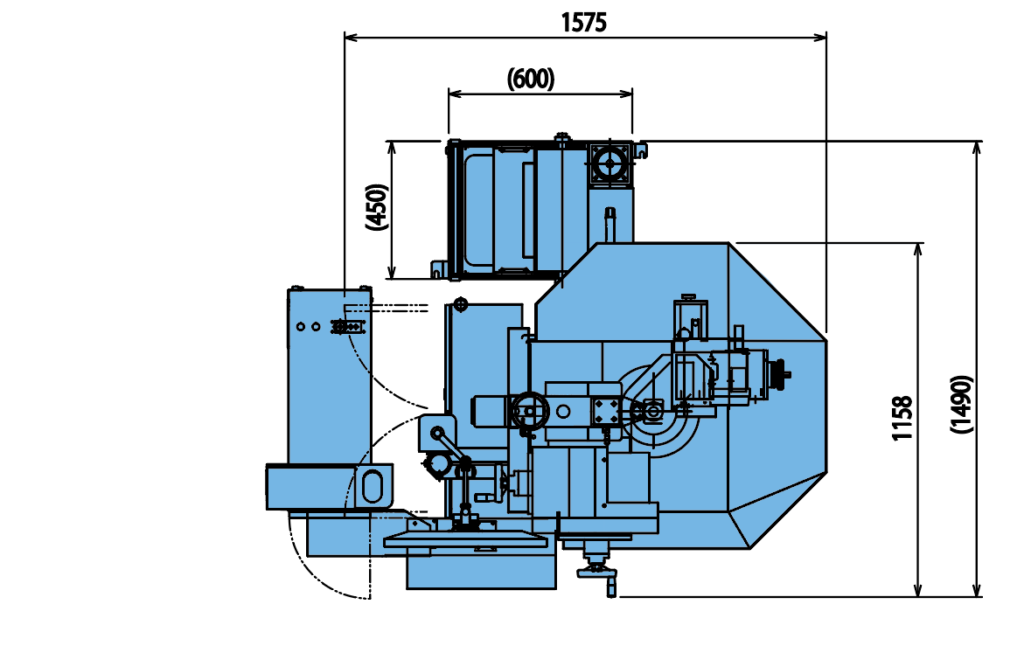

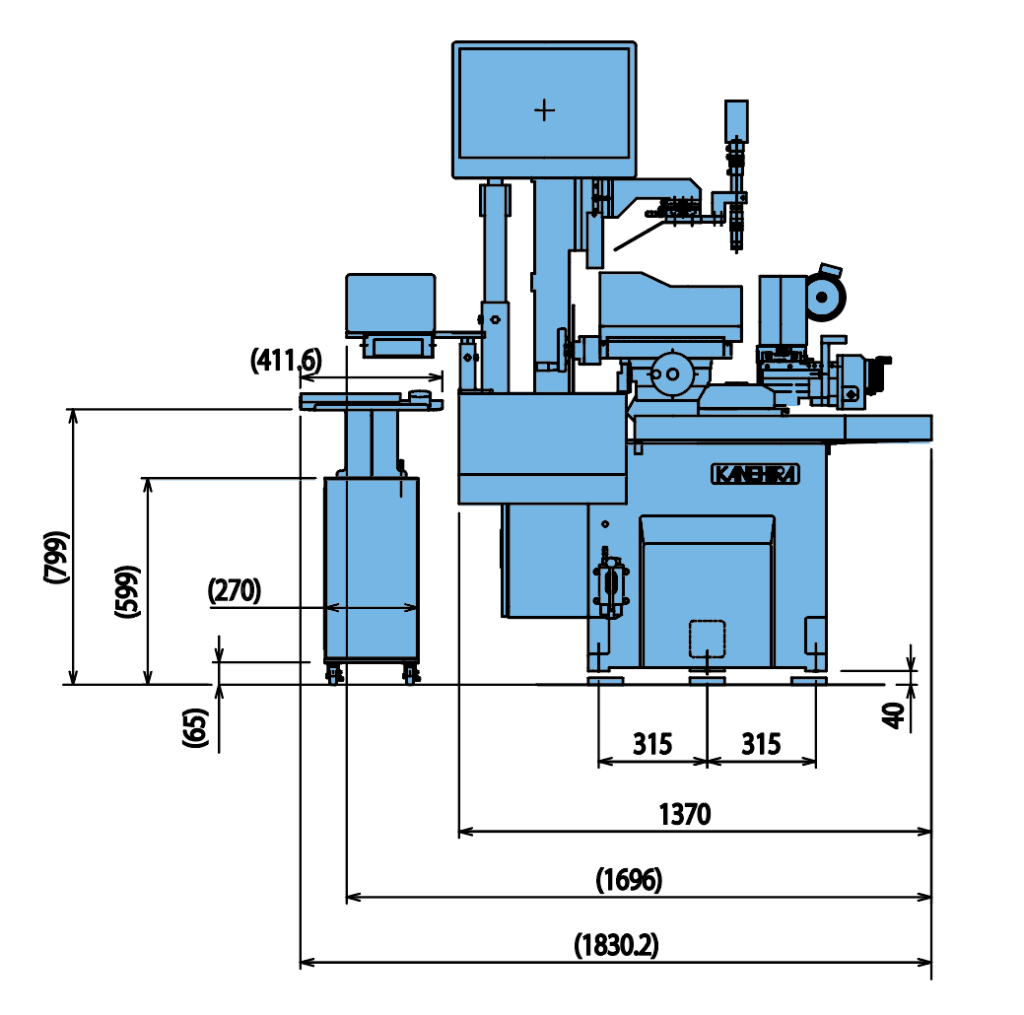

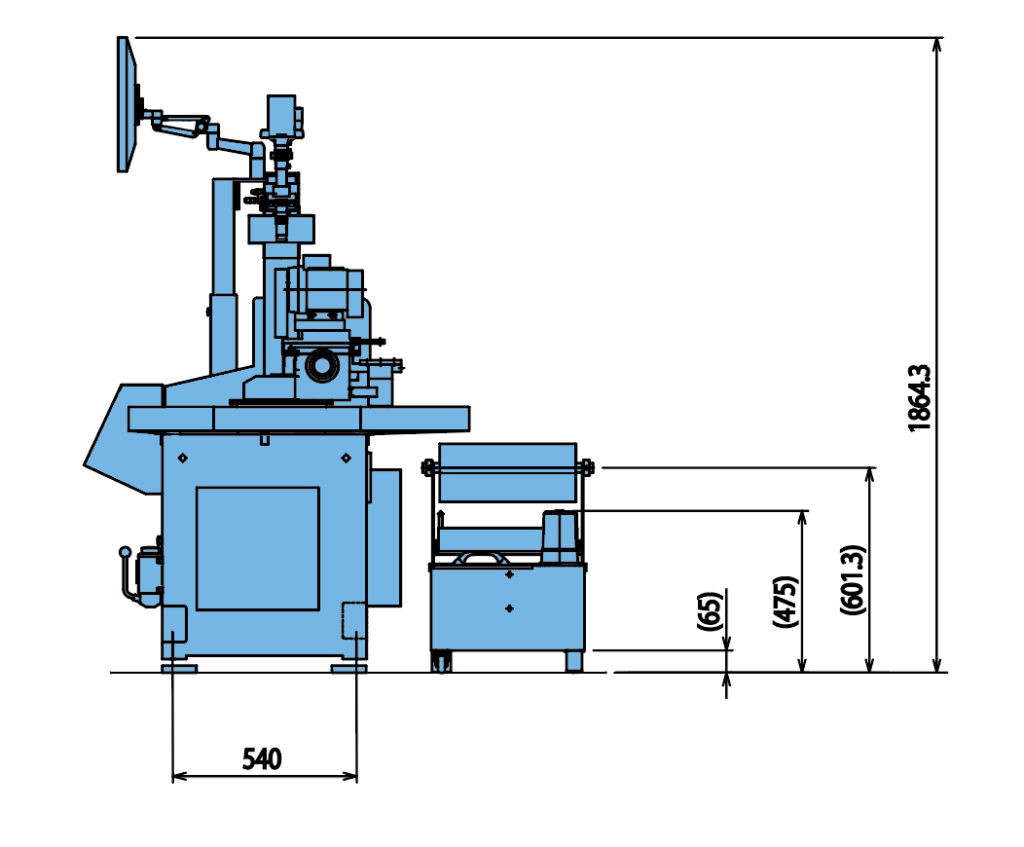

Machine dimension

CASES

OTHER PRODUCTS

Diamond Wheel Dressing Machine /CBN/Grinding Wheel(manual type)

DFM410

Diamond Wheel Dressing Machine /CBN/Grinding Wheel(manual type)

DFM510

PAGE TOP