SAF510

Diamond Wheel Dressing Machine /CBN/Grinding Wheel(CNC)

The SAF-series CNC form dressing and truing machines for superabrasive(Diamond,CBN) wheels are high-performance machines that display the power in the industry field where the highest value is given to the “Superthin”,”Complex shape” and “Complete form” superabrasive wheels.

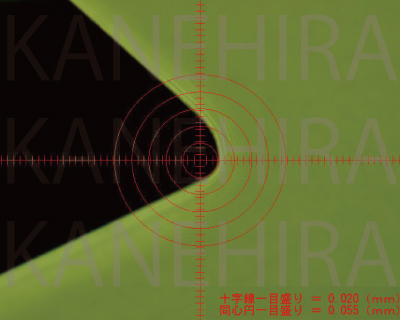

Sample by high accuracy forming wheel

Processing results

After customers process the diamondwheels for dia.0.09PCD drill-flute-recessing,1-1000 pieces of all are processed in a good state by customer’s grinding machine, and it gives 100percent satisfaction for concrete shape.

Also, the machine achive a good reproducibility in 10 times of same shape examination of dia.0.1PCB drill-flute-grinding.

The High Rigidity Guaranteed

We put our knou-how of machine development together,and guaranteed the high rigidity of the bed and whole machine structure.

The machine is high rigidity and low oscillation; the machine body is complete-box-type-structure and bed filled up with concrete.

The highly accuracy linear roller way are used on the table slide. It enable to have a rigid body and a accuracy movement. SAF410-CNC5-CCD reduce the machine-trace-line-error to a sub-micron-level by the center of gravity movement during the processing.

Normal Direction Control

The program operation keep the wheel control to face the normal direction all the time. It makes possible to process the outline accuracyly.

Digital CCD Camera

Digital CCD camera is installed in the measurment stand on the machine of gate type structure. It reduce a vibration and heat displacement to minimum.

Also,it show its ability for the high magnification measurement by saving various measurements and their images.

Magnificant of 200, dia.150mm Work circumference (Wheel for the drill-flute-grinding)0.02mm/div

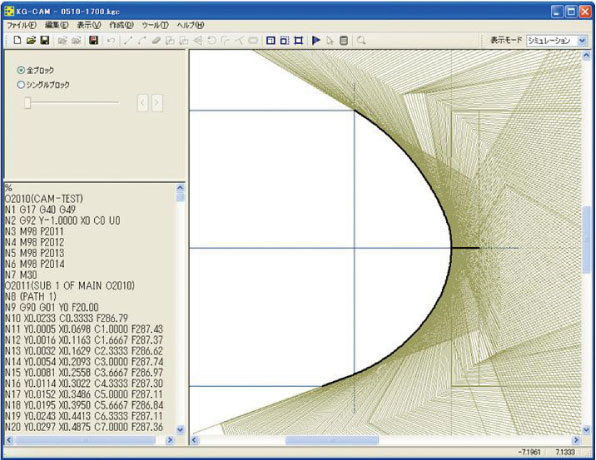

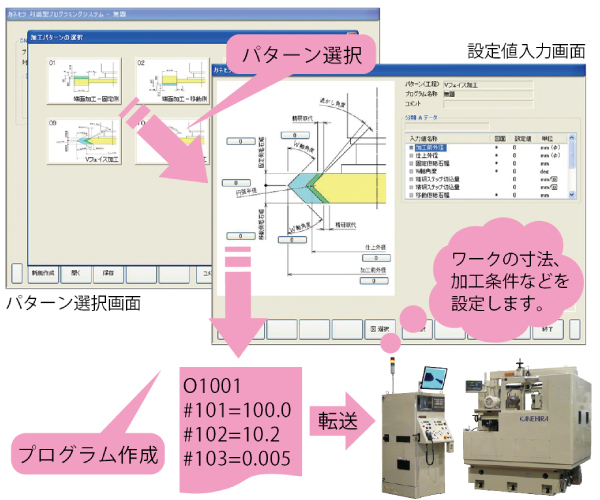

Various software/ CAM system

It helps your easy to operate this 5-axis machine.

A macro programming for a processing defined shape is easy by interactive programming system. In addition, KG-CAM can make easy to program for processing specific shapes with CAD drawings (DXF files) and multipoint data.

A screen of KG-CAM simulation.

Sample of shape pattern macro program

The Point of The High accuracy

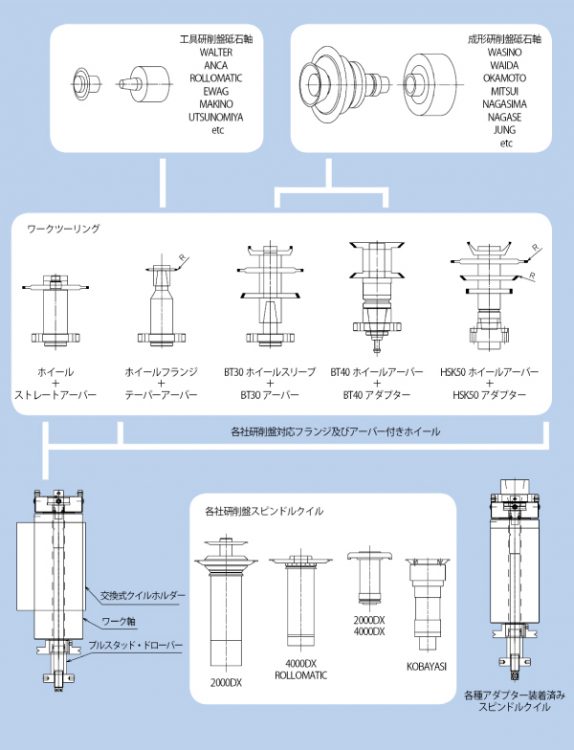

This machine support the rivision frange and multi-set-wheel with arbar of each companies.(cf. chart below a figure of touring)

It can set the spindle quill with diamond wheel removed from the griding machine,during processing,the intial abration of the wheel is reduced by suppressing the vibration to minimum.(It is important to be in a good condion of your spindle.)

It is able to adjust wheels (Diamond&CBNwheel) in the state you set on wheelarbars or franges in a single or multi. By this reason, you can possible to dress smooth and adjustable on the machine in the shortest time. In the processing, shortening of laege loss time and actual drive time improves because it does not need do smooth grinding and work on onboard dresser.

By exchanging various arbars and adapters in work spindle, franges and wheelarbars of deffirent machine support high accuracy. Also,the spindle quills that was installed various adapters and the spindle quills for each companies machines are installed by exchangeable quill holders; It makes adjusting possible higer accuracy.

Option

- Signal tower | Red Orange Green

- Control panel name plate | Each language

- 【Coolant unit】

Capacity-Coolant pump | 60L 60W

Capacity-Coolant pump| 100L 180W With simplified paper filter - 【Work spindle】

Spindle speed (Inverter use) | 25-250min-1

Exchangeble holder for spindle quill | φ45mm 1 set

Exchangeble holder for spindle quill | φ60mm 1 set

Exchangeble holder for spindle quill | φ70mm 1 set

Machine dimension

CASES

OTHER PRODUCTS

Diamond Wheel Dressing Machine /CBN/Grinding Wheel(CNC)

SAF75

Diamond Wheel Dressing Machine /CBN/Grinding Wheel(CNC)

SAF210

Diamond Wheel Dressing Machine /CBN/Grinding Wheel(CNC)

SAF410

Diamond Wheel Dressing Machine /CBN/Grinding Wheel(CNC)

SAF850

PAGE TOP